Spotlight on unique ice thermal energy storage strategies

As the sizzling days of summer persist into the fall, business owners and property managers throughout Southern California continue seeking ways to reduce escalating electricity costs for air-conditioning and refrigeration while utilities struggle to meet the region’s increasing cooling demands.

When it’s hot outside, air-conditioning (AC) is close to 50 percent of an average commercial building’s electrical costs, while at facilities with additional cooling needs, such as grocery stores or refrigerated food processing plants, electrical costs rise even higher.

Originally published Oct. 5, 2015, in the San Diego Business Journal special section “Sustainable San Diego.”

For utilities, commercial building AC is among the most expensive end uses to serve. Electrical demand for AC is highly variable, seasonal and creates high demand during midday and late afternoon. At the same time, refrigeration units require enormous amounts of uninterrupted power – a single supermarket freezer can use as much electricity in a day as three typical California households.

Thermal energy storage solutions

Most U.S. commercial buildings (up to 95 percent) are too small to justify central plants for cooling and refrigeration. For AC, they typically rely on multiple rooftop units that operate on a much smaller scale but consume a large amount of energy. Cold storage requires additional power-sucking refrigeration units. Both systems are highly inefficient during hot daytime hours, drawing the most electricity when utility costs are the highest.

But this situation is changing. Two California companies have developed systems that provide innovative and cost-effective means of reducing the daytime electrical demands of air conditioners and refrigeration units.

Ice Energy in Santa Barbara offers the Ice Bear, a plug-and-play addition for packaged rooftop AC systems; and Richmond-based Axiom Exergy manufactures the Refrigeration Battery for offsetting the power needs of cold storage systems. Both make ice at night when electricity costs are lowest and use the stored ice during the day for cooling, a process called ice thermal energy storage (TES).

Benefits to the grid

In addition to reducing utility costs through shifting a business’s electrical demand for cooling to nighttime, ice TES technologies also provide benefits to the grid, according to Jonathan Hart, a CSE project associate with the Self-Generation Incentive Program.

”These new systems will allow utilities to gain higher efficiency without having to install additional generation capacity, yet do not require direct connection to the grid as do most other energy storage systems,” Hart said.

Hart explained that ice TES units at various locations can be connected via smart grid communications technology and centrally controlled, by the manufacturer or the utility, to reduce grid pressures during periods of peak electricity demand almost instantaneously.

“These new systems perform best and offset the most electricity as outdoor temperatures rise, exactly the opposite of how traditional AC and refrigeration units operate,” Hart said.

Ice TES air-conditioning

Most Southern Californians know that when you turn up the AC, your utility bill goes up, but for commercial users it goes up even higher because they pay monthly electricity demand charges based on their highest usage, or peak demand. In San Diego, peak demand drives energy costs from about $20 per kilowatt (kW) at low demand periods to $42 per kW during high demand periods.

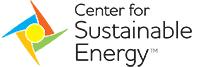

The Ice Bear, at about the size of an extra-large home freezer, attaches directly to most any commercial direct-expansion air-conditioning system, common for small to mid-sized buildings, as a retrofit or during new construction. It can directly offset an average of six kilowatts of peak demand for a minimum of six hours daily, shifting 36 kilowatt-hours of on-peak load to off-peak hours, according to Greg Miller, Ice Energy’s executive vice president for market development.

“At night, the Ice Bear pumps a refrigerant through its copper coils to freeze 450 gallons of water that is stored until its cooling energy is needed,” Miller said. “As daytime temperatures rise, the system shuts off the air conditioner compressor and replaces the cooling with the slowly melting supply of ice, reducing peak demand consumption.”

Ice Energy focuses most of its marketing on utility-based energy storage programs in which utilities purchase the units and work with the company to place them for free in locations where they will provide the most advantage to grid needs. Instead of upgrading grid components, building new power generation or purchasing power from other sources, the utilities are changing the customer’s capacities to offset peak periods. According to Miller, a utility in Maine avoided an $18 million investment in transmission upgrades with $6 million worth of Ice Bear systems.

In July, Southern California Edison entered into a 20-year contract with Ice Energy and NRG Energy for 25.6 megawatts of TES to offset peak load, which will entail installing about 1,800 Ice Bear units in Orange County starting early next year.

With California’s three big investor-owned utilities set to enact time-of-use electricity rates for residential customers in 2019, Ice Energy is poised to release a combination air conditioner with an ice TES system sized for home use called the Ice Cub. It will allow homeowners to shift up to four hours of peak demand use for air-conditioning consumption to nonpeak hours.

Ice TES refrigeration

Axiom Exergy (“exergy” means the amount of energy that can be harnessed for useful work) entered the ice TES industry in 2014 with the goal of transforming energy-intense commercial refrigeration systems in supermarkets into cost-saving opportunities. Grocery stores have all the electrical needs of other businesses with the addition of freezers and refrigerated cases that need to stay at a steady temperature even though some are open displays that allow the cold to mix with warmer air in the air-conditioned floor space.

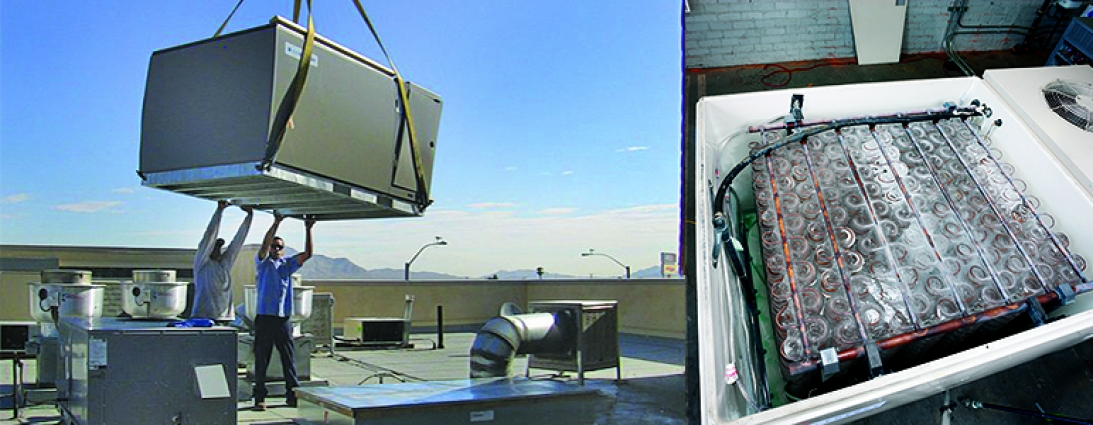

Axiom Exergy’s Refrigeration Battery integrates with existing cold storage systems to manage the electrical load. It “charges” by freezing tanks of saltwater at night and “discharges” during daytime peak demand times to supply refrigeration, allowing AC condensers and compressors to be shut off while keeping products cold. It can shift more than 100 kW of load for four to six hours daily, according to Amrit Robbins, Axiom Exergy’s co-founder and president.

“Refrigeration for supermarkets and cold storage facilities is a mission-critical part of their operations that produces electricity loads that until today could not be adjusted based on grid conditions or utility prices,” Robbins said. “This old paradigm of refrigeration energy use is completely incompatible with utility time-of-use rates and results in very high energy costs.”

In addition to load shifting, Axiom Exergy’s system also can serve as a backup cooling system to keep food cold during power outages – an even more important feature for some stores. Robbins said a Bay Area supermarket lost power for eight hours earlier this year, losing more than $300,000 worth of product. While most supermarkets have backup diesel generators, they are typically only powerful enough for emergency lighting and point-of-sales systems but not refrigeration.

Axiom Exergy’s business model is to install systems with a zero-cost lease contract that the customer pays for out of ongoing energy savings. They are also working with four utilities nationwide to set up pilot projects to demonstrate their Refrigeration Battery’s ability to provide grid services, including SDG&E.

Robbins said the company is in the process of installing its first full-scale system later this year at a major supermarket in California. They also have plans to install 25 or more systems for multiple supermarket chains in 2016.

Making the connection

While businesses generally do not consider air-conditioning or refrigeration upgrades until their units are due for replacement, the various utility programs, attractive offers made by manufacturers and state rebates make ice TES technologies worth considering sooner to reduce electrical load. The California Self-Generation Incentive Program (SGIP) will cover up to 60 percent of project costs for eligible ice TES systems. To further reduce up-front costs, businesses can use property assessed clean energy (PACE) financing or other green lending options.

CSE will assist in evaluating business energy needs and opportunities for applying ice TES and a wide range of other clean energy solutions. As a first step, take the Clean Energy Assessment at www.energycenter.org/assessment.