The transition to a clean energy future does not have just one solution. Rather, a combination of forward-thinking applications using a wide portfolio of efficient energy sources will help create a more sustainable pathway.

One currently underutilized tool that can play an important role in expanding clean energy development is combined heat and power (CHP). Traditionally reserved for large industrial facilities, such as steel mills and oil refineries due to their enormous concurrent need for both thermal and electric energy, recent technological advancements have led to higher efficiencies and lower costs, making CHP viable in new market sectors.

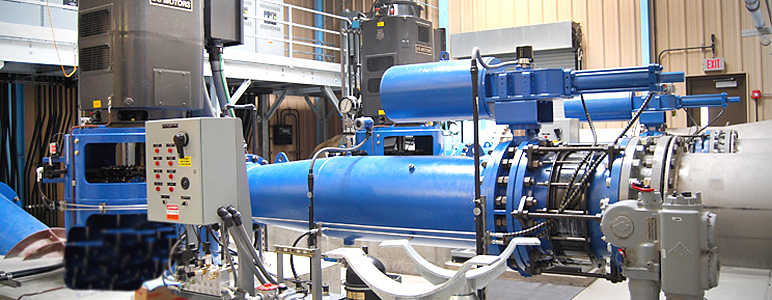

CHP is a type of cogeneration that typically uses an engine to generate electricity while simultaneously capturing "waste" heat from engine exhaust for energy recycling. Instead of sending the exhaust into the atmosphere, the thermal energy is captured and used in secondary applications such as space or water heating.

CHP advantages

CHP can reduce greenhouse gas emissions from electric generation and, when optimized, can achieve system efficiencies exceeding 70-80%. It can also operate with a biogas fuel supply, making it a renewable energy source. Wastewater treatment plants, food processing facilities and dairy farms are strong candidates for biogas production sites.

CHP is not a new technology. In 2008, CHP accounted for nearly 9% (85 gigawatts) of total U.S. electric capacity. A report by the Oak Ridge National Laboratory calculated that increasing that share to 20 percent by 2030 would lower U.S. greenhouse gas emissions by 848 million metric tons of CO2 annually (equivalent to taking 154 million cars off the road). The federal government is a proponent of CHP adoption, with President Obama calling for the deployment of 40 gigawatts of new CHP by 2020.

Although large-scale industrial installations create greater gains toward CHP goals, technological advancements mean it can now be applied in more diverse applications.

A good example of a smaller application is at Chaparral High School in Temecula, Calif., where CHP was installed to reduce operating costs. The school generates electricity on-site with five gas-fired microturbines and creatively uses CHP waste heat to both warm the school’s swimming pool and cool classrooms with a heat-driven absorption chiller. Previously, the school purchased all electricity and gas from the local utility and since CHP implementation has achieved impressive energy and economic savings. The first two microturbine units installed in 2001 (and still in operation) saved the school from $100,000 to $150,000 per year for the first 10 years, and the three new units are expected to yield even greater savings.

Future of CHP

The growth of CHP is largely dependent on educating business leaders, engineering professionals and decision-makers about the integration of CHP into their energy portfolios. That’s one of the reasons why the Obama Administration created the Department of Energy’s Combined Heat and Power Technical Assistance Partnership that CSE administers in the Pacific Region. In addition, CSE administers California’s Self-Generation Incentive Program, offering rebates for CHP and other clean energy projects in the San Diego Gas & Electric service territory.

Along with other energy industry partners, CSE is encouraging policy makers, utilities, energy agencies, local governments and others to assist CHP adoption by removing barriers, such as arbitrary siting and environmental permitting policies or high interconnection fees, and by incorporating CHP into planning initiatives and government building programs.

There is no single solution to a sustainable energy future, but a fresh perspective on CHP is one big step in the right direction.